V-Smart BIC-V Borehole Injection Control Valve™

Technical Overview – System Operation with Hydraulic Power Unit (HPU)

2. The valve sits above the bowls of a pump, either line shaft or submersible type, and is submerged below the static water level or maximum expected draw down level during pumping operation. The valve maintains a variable back pressure in the drop pipe to maintain well surface pressure at a safe margin above atmospheric pressure to prevent cascading water and air entrainment, while providing flow control into the injection well.

3. The valve maintains a minimal overall external diameter, as compared to other downhole control valves, enabling the valve to be located within smaller well casings, as small as 8” internal diameter.

5. The V-Smart™️ valve is hydraulically piston-actuated, without expanding bladders, therefore it can maintain a constant valve set point, regardless of flow or pressure changes in the system. Once driven to a set point, the V-Smart™️ valve will not move from position. This provides reliable and repeatable set point control with the ability to use a smaller valve with lower energy costs during pumping

7. Two hydraulic hoses, conforming to NSF-61 standards run from the surface level HPU down to the valve. These are strapped to the column pipe by the contractor during installation.

8. The hydraulic fluid is non-toxic, food grade mineral oil.

9. ASR Resources works with client and consultant control teams to utilize our Hydraulic Power Unit (HPU) to take a set of dry contacts to pulse the valve open or closed via client-provided PLC PID logic or we can provide the PLC functionality on board with control logic and programming provided for full automation. In those applications, we look at output from the well head pressure transmitter, submersible pressure transducer and flow meter to optimize flow into the well during injection, while maintaining a desired injection head at the surface and limiting mounding in the well. We can operate the valve based on either system flow or injection pressure as the primary operating control variable.

In doing so, we achieve the following:

- Protect the well construction from excessive flow by optimizing the flow with a soft and gentle injection start. There is no surge on the formation and no jetting of the well screen. We achieve a maximum sustainable injection flow rate into the well, infinitely adjustable up to the capacity of the column pipe.

- Protect the well from air entrainment by maintaining a desired injection head at the surface, thereby keeping well head pressure above atmospheric to prevent cascading water.

- Limit mounding in the well so that it does not exceed a predetermined upper limit, keeping the water level rise within the injection permit restrictions.

- Eliminate injection rate limitations commonly found when injecting through the pump bowls.

- Allow for high injection rates right up to the need to open annular by-pass piping in ASR wells with shallow static water levels, maximizing injection capacity when water is available.

- Allow for V-Smart™️ valve speed to be customized to site specific conditions, enabling finite control of the rate change per hydraulic unit open/closed command pulse. This smooths out the action of seeking a set point, eliminating the possibility of over-shooting the target, while maintaining a precise narrow dead-band operating range.

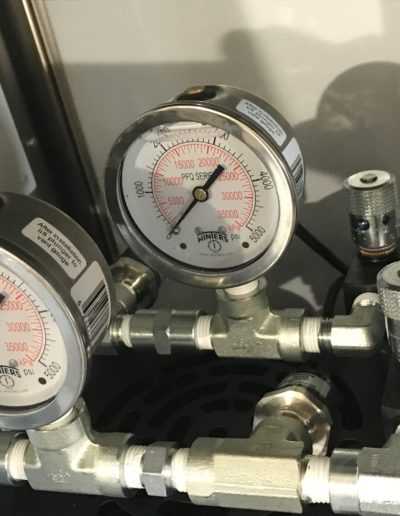

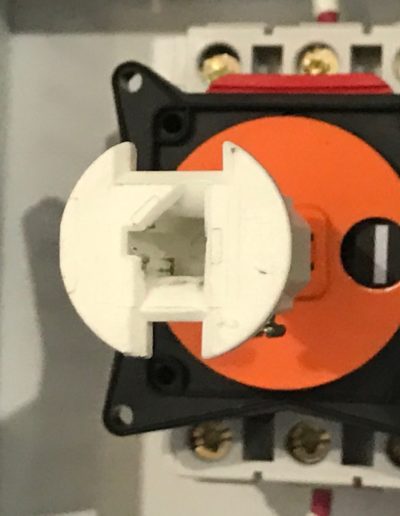

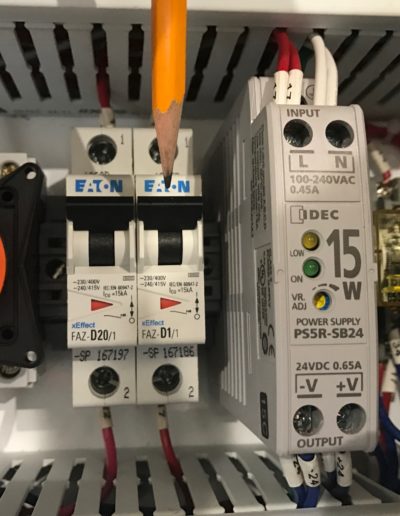

- The Hydraulic Power Units are constructed with Nema 3R, steel or stainless steel enclosures for pad, pedestal or wall mounting. HPU’s are powered with 120VAC, electric hydraulic pumps, with temperature activated fan ventilation and a front-mounted, lockable access door. HPU’s include internal door-mounted, Hand-Off-Auto selector switch, Pump Start – Pump Stop push buttons, and V-Smart™️ Valve Open/Valve Closed push buttons. Indication lights are provided for HPU Power On, HPU Pump Running, V-Smart™️ Valve Driving Open, V-Smart™️ Valve Driving Closed, V-Smart™️ Valve Full Open Position, and V-Smart™️ Valve Full Closed Position. The unit includes solenoid control of the opening and closing of the V-Smart™️ valve, pre-set and adjustable hydraulic operating pressure, independently adjustable valve operating speed controls in both open and closed directions of travel, local and remote indication of valve full open and full closed positions, hydraulically locked system to maintain a fixed valve position in the absence of open or closed commands, (3) 3,000 psi oil-filled pressure gages, mounted inside the inner door to show output pressure from the pump and output pressure on both individual hydraulic hoses leading to the V-Smart™️ valve, 3 gallon oil reservoir with sight gage and 10 gallons food grade mineral oil (shipped in separate container for filling oil reservoir on-site).

- Allow for V-Smart™️ valve speed adjustment for select operation modes, enabling the valve stroke, open/close action, to be set for dual purposes. Typical normal speed is for standard operation mode. Rapid speed is for well redevelopment mode for clog removal using the existing equipment.

- Field installation supervision, testing and start-up commissioning, are included at the well site for this and all other options. This includes installation supervision provided to the installation contractor for advisory oversight on proper valve handling, assembly to pipeline technique, proper handling of hose and strapping technique to the column pipe, purging hydraulic hoses of air and filling with mineral oil, filling HPU reservoirs with mineral oil, fitting attachment to assure hydraulic hoses connect and mate up correctly to the V-Smart™️ valves and the HPU’s, operational testing of valve stroke and of leak free connections. This also includes adjusting settings for speed of valve stroke for proper control characteristics, adjusting settings on valve open and valve closed position indication and training operations staff on the functionality and operation of the V-Smart™️ Valve/HPU system.

- Field installation supervision, testing and start-up commissioning, are included at the well site for this and all other options.

- Installation supervision is provided to the owner through the installation contractor for:

- Advisory oversight on proper valve handling

- Assembly to pipeline technique

- Proper handling of hose and strapping technique to the column pipe

- Purging hydraulic hoses of air and filling with mineral oil,

- Filling HPU reservoir with mineral oil,

- Fitting quick disconnect fittings to hydraulic hoses to assure proper connection and correct attachment to the V-Smart™️ valves and the HPU’s

- Operational testing of valve stroke and of leak free connections

- Adjustment of settings for speed of valve stroke for proper control characteristics

- Adjustment of settings on valve open and valve closed position indication

- Training operations staff on the functionality and operation of the V-Smart™️ Valve/HPU system.

V-Smart BIC-V Borehole Injection Control Valve™

Technical Overview – System Operation with Hydraulic Power Unit (HPU)

2. The valve sits above the bowls of a pump, either line shaft or submersible type, and is submerged below the static water level or maximum expected draw down level during pumping operation. The valve maintains a variable back pressure in the drop pipe to maintain well surface pressure at a safe margin above atmospheric pressure to prevent cascading water and air entrainment, while providing flow control into the injection well.

3. The valve maintains a minimal overall external diameter, as compared to other downhole control valves, enabling the valve to be located within smaller well casings, as small as 8” internal diameter.

4. The valve has a full bore internal diameter, which allows for line shaft passage through the center of the valve, while maintaining a high flow capacity with ultra low head loss during production pumping.

5. The V-Smart™️ valve is hydraulically piston-actuated, without expanding bladders, therefore it can maintain a constant valve set point, regardless of flow or pressure changes in the system. Once driven to a set point, the V-Smart™️ valve will not move from position. This provides reliable and repeatable set point control with the ability to use a smaller valve with lower energy costs during pumping

7. Two hydraulic hoses, conforming to NSF-61 standards run from the surface level HPU down to the valve. These are strapped to the column pipe by the contractor during installation.

8. The hydraulic fluid is non-toxic, food grade mineral oil.

9. ASR Resources works with client and consultant control teams to utilize our Hydraulic Power Unit (HPU) to take a set of dry contacts to pulse the valve open or closed via client-provided PLC PID logic or we can provide the PLC functionality on board with control logic and programming provided for full automation. In those applications, we look at output from the well head pressure transmitter, submersible pressure transducer and flow meter to optimize flow into the well during injection, while maintaining a desired injection head at the surface and limiting mounding in the well. We can operate the valve based on either system flow or injection pressure as the primary operating control variable.

In doing so, we achieve the following:

- Protect the well construction from excessive flow by optimizing the flow with a soft and gentle injection start. There is no surge on the formation and no jetting of the well screen. We achieve a maximum sustainable injection flow rate into the well, infinitely adjustable up to the capacity of the column pipe.

- Protect the well from air entrainment by maintaining a desired injection head at the surface, thereby keeping well head pressure above atmospheric to prevent cascading water.

- Limit mounding in the well so that it does not exceed a predetermined upper limit, keeping the water level rise within the injection permit restrictions.

- Eliminate injection rate limitations commonly found when injecting through the pump bowls.

- Allow for high injection rates right up to the need to open annular by-pass piping in ASR wells with shallow static water levels, maximizing injection capacity when water is available.

- Allow for V-Smart™️ valve speed to be customized to site specific conditions, enabling finite control of the rate change per hydraulic unit open/closed command pulse. This smooths out the action of seeking a set point, eliminating the possibility of over-shooting the target, while maintaining a precise narrow dead-band operating range.

- The Hydraulic Power Units are constructed with Nema 3R, steel or stainless steel enclosures for pad, pedestal or wall mounting. HPU’s are powered with 120VAC, electric hydraulic pumps, with temperature activated fan ventilation and a front-mounted, lockable access door. HPU’s include internal door-mounted, Hand-Off-Auto selector switch, Pump Start – Pump Stop push buttons, and V-Smart™️ Valve Open/Valve Closed push buttons. Indication lights are provided for HPU Power On, HPU Pump Running, V-Smart™️ Valve Driving Open, V-Smart™️ Valve Driving Closed, V-Smart™️ Valve Full Open Position, and V-Smart™️ Valve Full Closed Position. The unit includes solenoid control of the opening and closing of the V-Smart™️ valve, pre-set and adjustable hydraulic operating pressure, independently adjustable valve operating speed controls in both open and closed directions of travel, local and remote indication of valve full open and full closed positions, hydraulically locked system to maintain a fixed valve position in the absence of open or closed commands, (3) 3,000 psi oil-filled pressure gages, mounted inside the inner door to show output pressure from the pump and output pressure on both individual hydraulic hoses leading to the V-Smart™️ valve, 3 gallon oil reservoir with sight gage and 10 gallons food grade mineral oil (shipped in separate container for filling oil reservoir on-site).

- Allow for V-Smart™️ valve speed adjustment for select operation modes, enabling the valve stroke, open/close action, to be set for dual purposes. Typical normal speed is for standard operation mode. Rapid speed is for well redevelopment mode for clog removal using the existing equipment.

- Field installation supervision, testing and start-up commissioning, are included at the well site for this and all other options. This includes installation supervision provided to the installation contractor for advisory oversight on proper valve handling, assembly to pipeline technique, proper handling of hose and strapping technique to the column pipe, purging hydraulic hoses of air and filling with mineral oil, filling HPU reservoirs with mineral oil, fitting attachment to assure hydraulic hoses connect and mate up correctly to the V-Smart™️ valves and the HPU’s, operational testing of valve stroke and of leak free connections. This also includes adjusting settings for speed of valve stroke for proper control characteristics, adjusting settings on valve open and valve closed position indication and training operations staff on the functionality and operation of the V-Smart™️ Valve/HPU system.

- Field installation supervision, testing and start-up commissioning, are included at the well site for this and all other options.

- Installation supervision is provided to the owner through the installation contractor for

- Advisory oversight on proper valve handling

- Assembly to pipeline technique

- Proper handling of hose and strapping technique to the column pipe

- Purging hydraulic hoses of air and filling with mineral oil,

- Filling HPU reservoir with mineral oil,

- Fitting quick disconnect fittings to hydraulic hoses to assure proper connection and correct attachment to the V-Smart™️ valves and the HPU’s

- Operational testing of valve stroke and of leak free connections

- Adjustment of settings for speed of valve stroke for proper control characteristics

- Adjustment of settings on valve open and valve closed position indication

- Training operations staff on the functionality and operation of the V-Smart™️ Valve/HPU system.