Submersible Pump

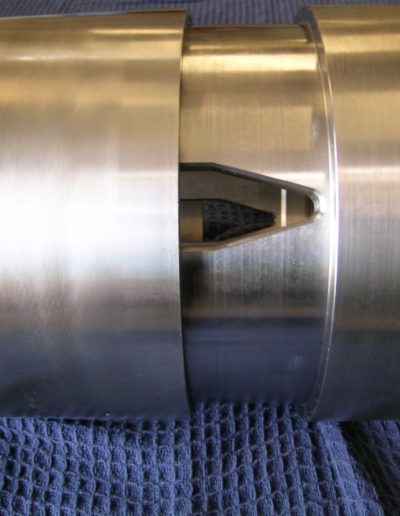

For submersible pumps, the configuration is similar to a vertical turbine pump application but without the line shaft passing through the center of the valve. The V-Smart BIC-V™ valve sits above the pump bowls in the column pipe string. During injection, water flows through the unobstructed (no line shaft) center of the valve and exits the valve through the machined injection ports. Based on the well data provided, these ports are carefully sized and custom-machined to provide the best control characteristics. The outer sliding sleeve is hydraulically actuated to slide up and expose the injection ports, with the total required valve stroke being determined by the desired injection flow rate. During pumping operations, the valve sliding sleeve is actuated fully closed, allowing recovery pumping to pass up through the center of the valve to the surface. Because the V-Smart BIC-V™ is designed with a full-port internal diameter, it allows for very low head loss during pumping operations. This helps keep the pump within an energy efficient range on the pump curve. The compact size allows the valve to fit into smaller casing diameters, as small as 8″. Depending on required flow rates during injection and recovery pumping, the V-Smart BIC-V™ valve is often sized one or two sizes smaller than the adjoining column pipe.